- About

Backed by Decades of Innovation

For 50 years, Intralox’s technology has enhanced safety and productivity around the world.

Hydrolox™ is the brand name applied to engineered polymer traveling screens invented and supplied directly by Intralox, who has been supplying screens directly to the water-extracting world for more than 20 years. Positively driven and chain free, our screens are built to handle extreme debris loads and to remain in the water for the entirety of their lives.

Our Story

Intralox identified that the issues faced by water screen users were nearly the same as those present in the traditional conveyor belt market: Conveyor and screen manufacturers both provided high-maintenance products with low reliability. We decided the water screen space needed reliable, long-lasting products designed and customized to address customers’ specific needs.

Hydrolox™ screens are used in any application in which coarse or fine mesh screening protection is needed to reduce maintenance costs, protect downstream equipment to increase its uptime, and meet local regulations. By utilizing a continuous engineered polymer mesh and eliminating metal drive chains and all underwater moving parts, Hydrolox screens have dramatically reduced maintenance costs and increased productivity across all industries.

About Hydrolox Water Screen Technology

Positive drive mechanism

Eliminates side chains, which are the biggest source of maintenance problems in traditional screens

Proprietary engineered polymer mesh screening material

Does not corrode and minimizes biofouling

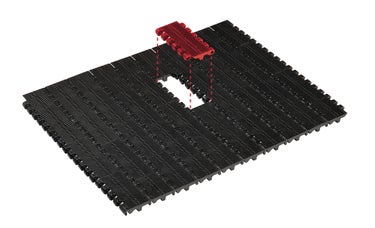

Modular design

Enables screens to be built up to 5 m wide, meeting project goals with fewer screens and simpler layouts

Unique frame structure

Uses high strength steel to create an extremely strong and rigid frame that enables the system to handle extreme debris loads caused by storms, floods and even events such as jellyfish swarms

The Engineered Polymer Mesh Concept

Our screens are made from engineered polymer modules assembled in an interlocked, bricklayed pattern with full-length hinge rods—an inherently strong design. These modular components allow for fast, on-site maintenance, eliminating the need to replace the entire screen. All polymer components are molded in-house and we maintain an extensive inventory in order to meet both your normal and emergency delivery needs.