MAWSS Reduces Cleaning Time by 96% with Hydrolox Screens

Case StudyMobile Area Water & Sewer System

Location

Mobile, Alabama USA

Industry

Municipal/Desalination Water

Solution

Debris Removal

The Mobile Area Water & Sewer System (MAWSS) operates two water treatment stations that together treat up to 90 million gallons of water per day. The company had been using a series of passive metal mesh screens to filter and remove debris at the intake. Cleaning the debris screens, which included removing algae that would accumulate on the mesh wire, was difficult and time consuming. Each day, a worker would manually clean the screens for an hour (on average). In addition, the screens had to be removed once each month, pressure washed, and reinstalled. This supplementary deep-cleaning process required two workers and took an entire eight-hour workday.

The Hydrolox screens are maintenance and trouble free. In my opinion, this is the best investment MAWSS has made at Big Creek Pumping Station.

Steven Davis

MAWSS Site Superintendent

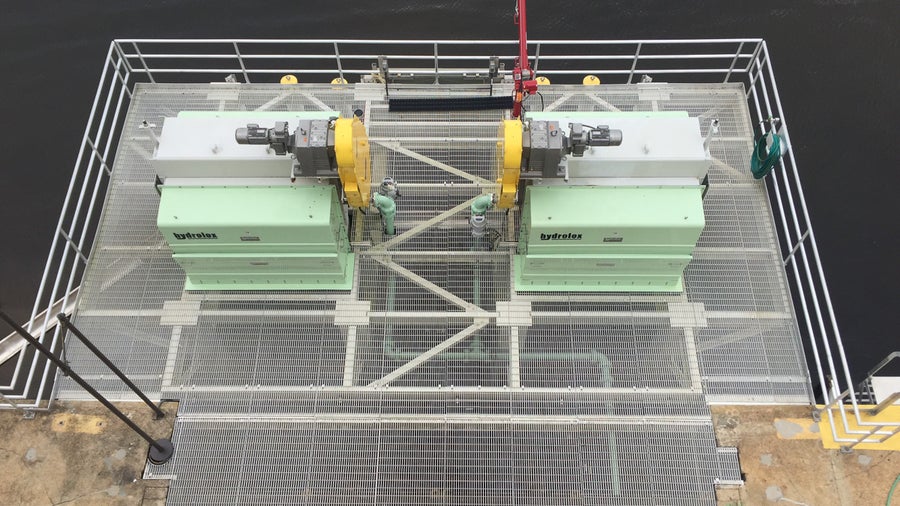

Seeking a solution that would allow them to decrease cleaning time and increase operational efficiency, MAWSS officials chose to replace their passive screens with two Hydrolox Series 6000 traveling water screens. Hydrolox screens substantially reduce cleaning needs and operation, maintenance, and ownership costs for debris screening at water intakes. Made from engineered polymer modules, Hydrolox traveling screen systems are specifically designed to operate continuously (24/7/365) when required.

Since installing the Hydrolox screens in August 2016, MAWSS has significantly enhanced its cleaning and maintenance processes. Because the screens require no manual cleaning, maintenance has been reduced to a simple, five-minute procedure* performed by a single worker once every two weeks. The screen’s open-slot design, smooth surface, and 1-in deck thickness help facilitate effective cleaning, and also prevent filamentous algae from “stapling” around the mesh. Overall, MAWSS has reduced its cleaning and maintenance levels from 442 labor-hours per year to just 16—a reduction of more than 96%. They have also noticed improvements downstream, including better water quality and reduced maintenance needs (for downstream MAWSS equipment).

*Cleaning the spray header bar and greasing bearings and drive